Applications

DuraFlex Pro ultra flexible relining for masonry chimney. Use with gas, wood pellet, oil, or wood appliances. Applications include: fireplace inserts, furnaces, boilers, and water heaters.

DuraFlex SW smooth wall flexible relining for masonry chimney. Use with gas, wood pellet, oil, or wood appliances. Applications include: fireplace inserts, furnaces, boilers, and water heaters.

DuraFlex 316 flexible relining for masonry chimney. Use with gas, wood pellet, oil, or wood appliance. Applications include: fireplace inserts, furnaces, boilers, and water heaters. 316 is designed for use in harsher conditions, for more resistance to corrosion, such as coal.

DuraFlex 304 flexible relining for masonry chimney. Use with gas, wood pellet, oil, or wood appliances. Applications include: fireplace inserts, furnaces, boilers, and water heaters.

Materials and Construction

DuraFlex Pro: Single-wall .005" 316 stainless steel.

DuraFlex SW: Single-wall .005" overlapped 316 stainless steel (totalling .010"). Overlapped to create smooth inner wall.

DuraFlex 316 & 304: Single-wall .005” 316 or 304 stainless steel.

Clearances

DuraFlex Pro: 0" clearance for gas, oil, and pellet applications. 1" clearance to masonry for wood-burning applications. Insulation is required for 0" clearance to masonry for wood-burning.

DuraFlex SW: Clearances 0" clearance for gas, oil, and pellet applications. " clearance to masonry for wood-burning applications. Insulation is required for 0” clearance to masonry for wood-burning.

DuraFlex 316 & 304: 0" clearance for gas, oil, and pellet applications. 1" clearance to masonry for wood-burning applications. Insulation is required for 0" clearance to masonry for wood-burning.

Diameters

DuraFlex Pro & SW: 3" - 12".

DuraFlex 316 & 304: 3" - 8".

Listings

DuraFlex Pro: Listed to UL 1777 and ULC S635 (MH45609).

DuraFlex SW: Listed to UL 1777 (MH45609).

DuraFlex 316 & 304: Listed to UL 1777 and ULC S635 (MH45609).

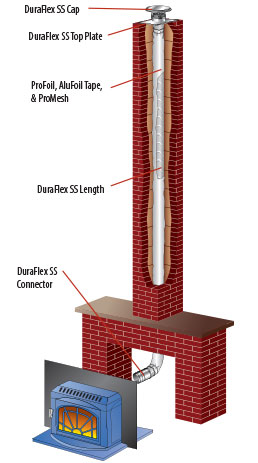

Refer to our Typical Venting Installation drawings to select the appropriate component parts for your installation.

- The inner pipe diameter should match the outlet size of the appliance.

- Check the appliance manufacturer’s installation instructions to confirm which types of vent configurations are permitted (i.e. horizontal, vertical, chimney reline, etc.). Also, check for any venting restrictions such as maximum horizontal run, minimum and maximum vertical rise, maximum offset, etc.

- Be fire safe! Use proper support and bracing. Follow local building codes and have your venting system inspected.

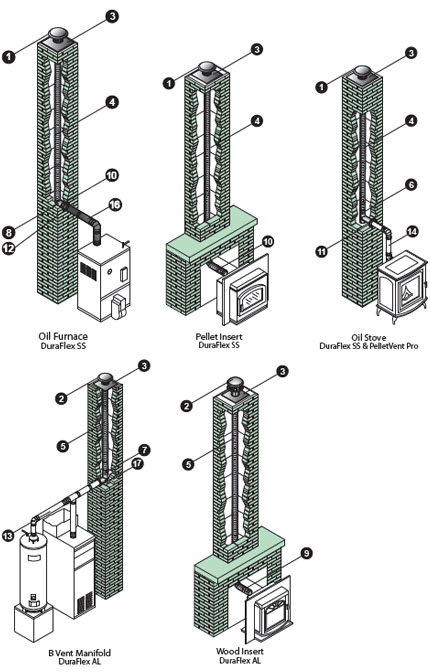

More Typical Installations:

| Installation Key |

| 1 | DuraFlex SS Cap |

| 2 | DuraFlex AL Cap |

| 3 | DuraFlex Top Plate |

| 4 | DuraFlex (SW, Pro, 304, 316) Length |

| 5 | DuraFlex AL Length |

| 6 | DuraFlex SS Tee |

| 7 | DuraFlex AL Tee |

| 8 | DuraFlex Mortar Sleeve |

| 9 | DuraFlex AL Coupling |

| 10 | DuraFlex SS Connector |

| 11 | PelletVent Pro Appliance Adapter |

| 12 | DuraBlack Trim Collar |

| 13 | Rigid Type B Gas Vent |

| 14 | Rigid PelletVent (L Vent) |

| 15 | ProFoil Insulation, AluFoil Tape & ProMesh |

| 16 | DVL or DuraBlack Pipe |

| 17 | Pipe Collar (B-Vent) |

Planning Your Installation:

| 1 | Verify the venting requirements of the appliance used. Choose the liner system appropriate for the appliance and installation. |

| 2 | Refer to the Typical Installations for the type of liner installation similar to your situation. Identify the needed parts for installation. |

| 3 | The size of the liner should match the outlet size on the appliance or the size of the vent/manifold that penetrates into the masonry chimney. |

| 4 | Determined the length of the liner needed. |

| 5 | Make sure of a proper fit for the Top Plate of the reliner to provide a secure, leak-proof installation. |

| 6 | If a free-standing appliance is used, select the vent or stovepipe pieces to connect from the appliance to the liner (refer to the appropriate section of catalog). |

| 7 | Important! Check to be sure the installation complies with all local and national code requirements, including clearance to combustibles. Contact the local building inspector for permit requirements. |

Design Recommendations

- The following design recommendations are intended only as a general guideline to assist in the design and selection of liner components for your installation. Always read and follow DuraVent Installation instructions (enclosed with the cap or support box) before installing DuraFlex. Installation instructions can be viewed online at www.duravent.com, under catalogs and instructions.

- Before relining a chimney, it should be cleaned and inspected to verify the integrity of the mortar and masonry. In addition, have a certified chimney professional determine if the masonry was constructed with 0” or 1” clearance to the surrounding combustibles. This is an important fire safety issue that may have an influence on how the liner is installed.

- Be sure to select the proper liner for the application. DuraFlex SS is used for appliances that use oil, wood, or wood-pellets for fuel; DuraFlex AL is for a non-condensing gas appliance. Refer to the appliance manufacturer for installation requirements affecting venting. Keep the vent path as straight as possible for best performance.

DuraVent is the first manufacturer to have a UL-listed relining system for factory-built chimneys to be used with solid-fuel appliances in the USA. When a homeowner installs a wood-burning insert into an existing UL127-listed fireplace, relining the existing chimney is critical for performance and safety. Check installation video on our youtube channel

Product Bulletin:

What does the UL listing cover?

All 127, 103, or 103HT chimneys

Insulated chimneys- all sizes with 2” clearance

Air cooled - clearance based on diameter

All Duravent UL1777 systems up to 8”

Flex does not need insulation.

Air Cooled Chimney Coverage:

Up to 8” I.D. chimneys with at least 1 ¼” wall (ex. 8x10½)

6x8½ is OK, 8x11 is OK

Up to 8” I.D. chimneys require at least 1 ½” clearance

Larger chimneys with at least 1 ½” wall (ex. 10x13)

9x12 is OK, 10x14 is OK, 16x19 is OK

Chimneys larger than 8” require at least 2” clearance

Factory-Built Reline Kit includes:

Cap

Storm Collar

Support Bracket

Ventilation Disk

Centering Bracket

DuraLiner 12” Length

Flex Connector

Flex Length (25’ or 35’)

Adjustable Band

Flex Adapter