Applications

VFT flexible liners are used for upgrading or restoring masonry chimneys that vent Category I natural gas, propane or oil appliances, wood or pellet stoves, fireplaces and fireplace inserts. VG flexible liners are top performers when used to line masonry chimneys venting Category I gas-fired boilers, furnaces, space and water heaters.

Materials and Construction

VFT Single-wall, .006" 316 stainless steel. Continuous weld delivers a strong, air and water tight flue gas conduit.

VG Single-wall, .006" AL29-4C stainless steel. Continuous weld construction.

Clearances

VFT 0" clearance to masonry chimney for oil and gas. With TherMix or ProFoil insulation 0" clearance for solid fuels.

VG 0" clearance to masonry for gas appliances.

Diameters

3", 12"

Listings

UL Listed to UL 1777 and ULC S635 (MH11476).

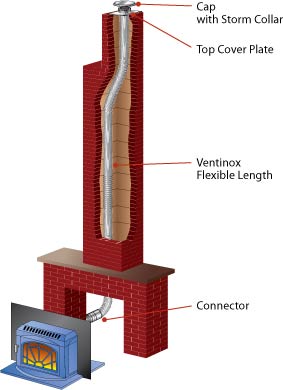

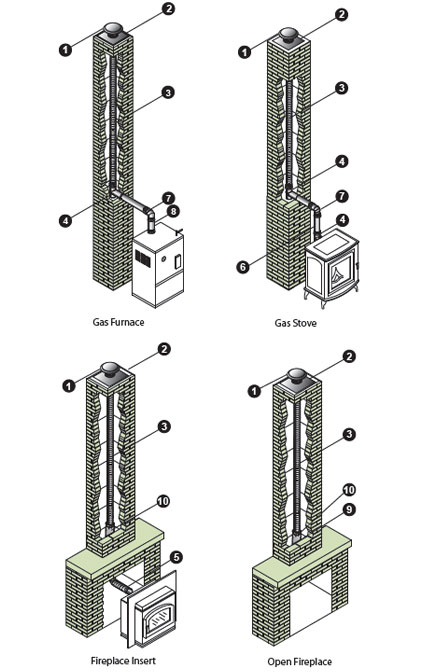

Refer to our Typical Venting Installation drawings to select the appropriate component parts for your installation.

More Typical Installations:

| Installation Key |

| 1 | Rain Cap w/Storm Collar |

| 2 | Top Cover Plate |

| 3 | Flex Length |

| 4 | Tee with Removeable Snout |

| 5 | Sleeve |

| 6 | Rigid Type B Gas Vent or Rigid Pipe Length |

| 7 | Adjustable Elbow |

| 8 | FasNSeal Universal Appliance Adapter or DuraFlex Appliance Adapter |

| 9 | Bottom Plate w/Collar |

| 10 | ProFoil w/ProMesh or Thermix |

Planning Your Installation:

| 1 | Verify the venting requirements of the appliance used. Choose the liner system appropriate for the appliance and installation. Note: VFT is recommended for all fuels and VG is the best choice for gas. |

| 2 | Refer to the Typical Installations for the type of liner installation similar to your situation. Identify the needed parts for installation. |

| 3 | Venting for a fireplace requires the correct liner size for proper drafting. The size of the liner should match the outlet size on the appliance. |

| 4 | Determined the length of the liner needed. |

| 5 | If connecting two or more appliances to a common vent, be sure to connect the higher BTU appliance below the lower BTU appliance. |

| 6 | Make sure of a proper fit for the top plate of the relining to provide a secure, leak-proof installation. |

| 7 | If a free standing appliance is used, select the vent or stovepipe pieces to connect from the appliance to the liner (refer to the appropriate Simpson Dura-Vent Catalog Section). |

| 8 | Important! Check to be sure the installation complies with all local and national code requirements, including clearances to combustibles. Contact the local building inspector for permit requirements. |

Catalogs:

Installation Instructions:

Sales Sheets:

Bulletins: