Applications

DuraSeal® single wall (DS 3"-24", DSLS 26"-36") or double wall (DSD 3"-24", DSLD 26"-36") is a special stainless steel vent system for gas fired appliances listed as Catefory I, II, III, and IV or in Canada as Type BH Gas Venting as noted in ULC-636, with a maximum operating temperature of 550°F (288°C), and a maximum rated positive pressure of 35" water column. It can also vent listed gas or oil fired appliance rated to be vent with TYPE L low temperature venting system (DSD & DSID only). DuraSeal® must be installed by an experienced professional familiar with the operation and maintenance of heating appliances and venting. Before installing this product, examine all components for possible shipping damage and read the complete installation manual. Failure to follow proper installation procedures, including vent pitch and improper appliance connections, may cause unsafe conditions.

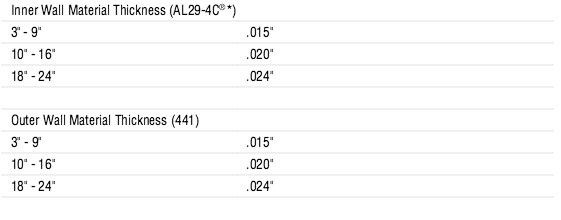

Materials and Construction

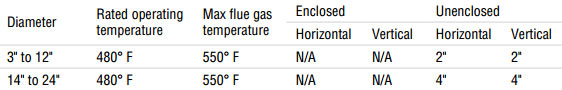

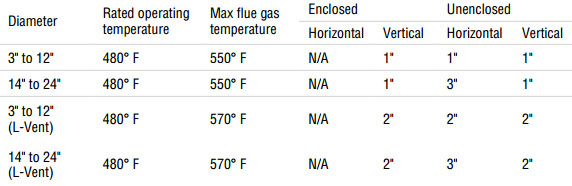

Clearances

DuraSeal Single Wall

DuraSeal Double Wall

Diameters

3"-36"

Listings

UL-1738/UL-1777/ULC-S636

Effective Length:

When assembling two parts together, the joint will overlap 2-3/8". So effective length is normal length minus 2-3/8".

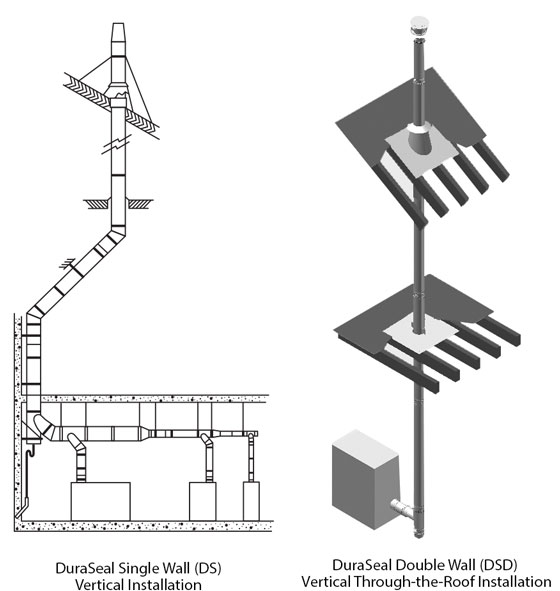

Vertical Installation Requirements:

- The vent system must terminate at least 3 feet above the roof line and at least 2 feet higher than any portion of the building within 10 feet. This limitation can be removed if an engineering analysis demonstrates normal and safe operation of appliance.

- When terminated at a height of more than 10 feet, the stack must be supported by a Guy Section.

- The vent system must terminate with one of the DuraSeal terminations.

Each DuraSeal vent length and component features our Secure Lock system and Viton® o-ring gasket, which insure a gas- and water-tight system. Parts are easily pushed and fastened together instantly and effortlessly. DuraSeal can be taken apart and easily reassembled, making inspection, maintenance or rerouting of DuraSeal systems simple and straightforward.

DuraSeal provides an extensive range of components and accessories, made of stainless steel, allowing any type of installation. On top of the common components, we also offer special parts that help simplify installation, such as the 2-degree elbow and 43-degree tee (simplifying pitching on a horizontal vent) or the 18" and 36" adjustable lengths (to help maximize ease of installation). Connecting the DSD to a heater is effortless with one of the many adaptors approved by heating appliance manufacturers. Heating equipment can be operated immediately upon completing a DuraSeal installation, as no cure time or cleanup is required.

Note: If viton caulking is used at the boiler adaptor or an adjustable length, there is a cure time of 24 hours.

When venting Category I, II, III, or IV appliances or type L vented apliances, DuraSeal must be used for the entire length of the system. Do not mix pipe, fittings, or joining methods from different manufacturers. Every vent system must be planned and installed for optimum performance and safety. The venting system must be free to expand and contract and must be supported in accordance with these instructions. (Check for unrestricted vent movement through walls, ceilings, and roof penetrations). Refer to the gas appliance manufacturer’s instructions to determine venting requirements and limitations with respect to installation and use of the appliance. It is the responsibility of the installer to contact local building and fire officials concerning any installation restrictions and/or inspection requirements that may apply. Permits may be required before starting and installation.

- If required by the appliance manufacturer, a Drain Tee Cap must be located as close as possible to the appliance flue outlet. Depending on the arrangement of the vent, more than one drain may be required. Unless a Drain Tee Cap is supplied with the appliance, install a DuraSeal Drain Tee Cap.

- More than one Category II, III, or IV appliance may not be connected into the same vent system unless the appliance manufacturer specifically approved such a system and the appliance is designed for multiple venting.

- DuraSeal must not come in contact with plumbing or electrical systems.

- Maintain rated clearances to combustibles over the entire length of the vent system.

- DuraSeal shall not be routed into, through, or within any vent, such as an existing masonry or factory-built chimney that is connected to another appliance.